Hi

I have ridden a few gsx-r 750's and I've always liked the feel of the showa gsx-r forks. I think they are some of the best oem forks in any street bike (the öhlins equipped bikes not included). They never feel harsh and have enough firmness for sportier, even track riding.

I have installed some k-tech internals in my 900-ss forks but had a cocked thread in the stock damper rod and I haven't been able to get the k-tech valving to work exactly as i would like, so I thought I would like to try and transplant some gsx-r fork internals to my 900 superlight forks. The k-tech valving seems to have too much high-speed rebound and that would be possible to correct by removing a shim or two from the rebound stack, but because the cocked threads I don't feel like putting any more work to the 900-ss cartridges.

I gathered some information from the net and found the complete internals including fork caps for k4-5 gsx-r 600/750 on ebay quite cheap. They are made by Showa and should be quite high quality compared to the 900ss forks. They have a proper rebound circuit too.

The gsx-r internals are almost the same length as the 900-ss internals. The bottom bolt is exactly the same and so is the fork cap. The gsx-r has blue/gold anodized fork caps and I wanted to keep the stock SS look so I took the caps apart and found that the only difference in the fork cap parts is the rebound adjuster screw/rod and the middle part the damper rod screws in. The damper rod in the gsx-r cartridge is 12mm and 900ss is 10mm, so the middle part has to be taken from the gsx-r. The fork cap body and the preload adjuster nut of the 900-ss forks can be used in with the gsx-r cartridges. You can keep the aluminum-colored cap parts from the 900-ss and swap them to the gsx-r cartridges.

The gsx-r cartridge outer diameter is 24mm and the 900-ss 22.6mm. The 900-ss forks have a 1,3mm thick cup-shaped spacer below the cartridge bottom end that needs to be removed to fit the gsx-r cartridge.

The lengths of the cartridges from bottom to fork cap lip are

900-ss bottomed out 55,9cm, topped out 67,2cm

gsx-r k4 55,3 - 66,9cm

The bottomed out depth of the 900 fork from the bottom of the fork leg to the top of the top tube is 55,2mm. So the stock cartridge will bottom out before the fork leg does. Only if you remove the plastic bottom-out piece (it is removed in the pic below), will the fork leg bottom out before the cartridge. The gsx-r cartridge will bottom out shorter than the 900-ss cartridge (and 1mm before the fork leg) so it should not be an issue.

I assembled the fork legs today with gsx-r cartridges and they seem to fit ok. However, I forgot to take the gsx-r springs and spring spacers with me so I had to leave them out. So no test ride yet.

The whole swap can be done without removing the forks from the bike, only the front wheel needs to come off, so it's quite an easy job.

I'll report the riding impressions as soon as I can get the springs (I forgot them to another town so it will take a few days).

The fork length will be about 4mm shorter after this mod

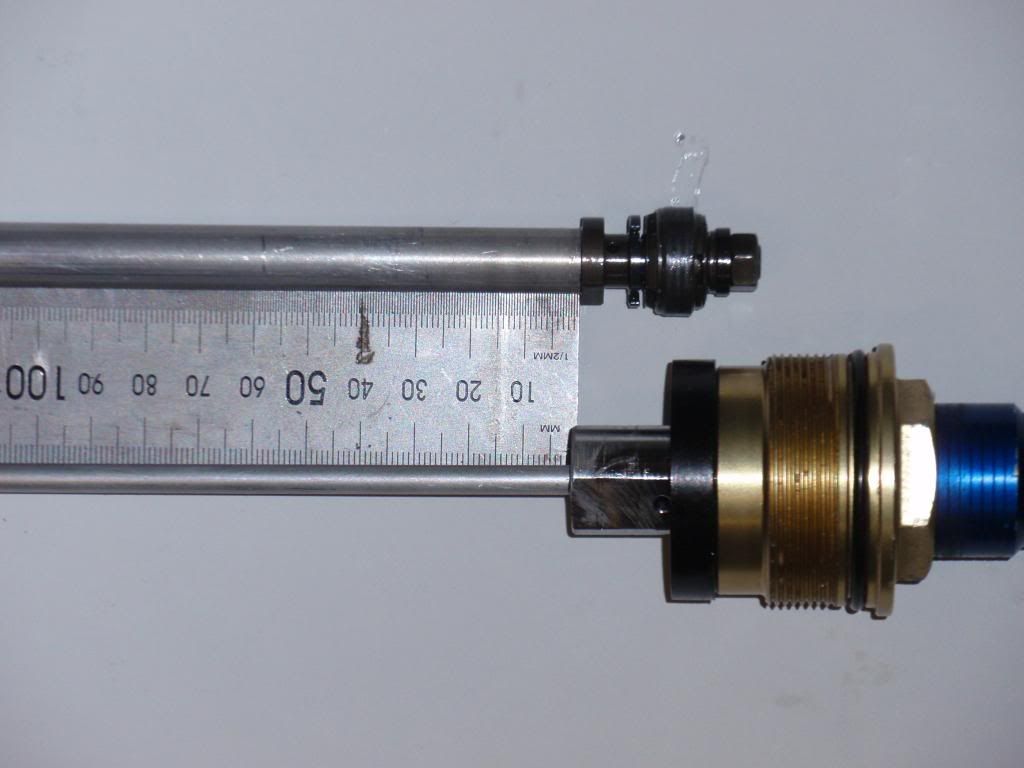

a pic from the cartridges side by side (the fork caps are already swapped)

![Image]()

I think this could be a cheaper and easier alternative to swapping to sbk forks or re-valving the stock cartridges, if you can just find the gsx-r internals cheap. I think some other year gixxer fork internals would probably work too (k1-3 and srad 750) but I can't confirm it because I don't have the parts. If someone has them, please post the measurements.

I have ridden a few gsx-r 750's and I've always liked the feel of the showa gsx-r forks. I think they are some of the best oem forks in any street bike (the öhlins equipped bikes not included). They never feel harsh and have enough firmness for sportier, even track riding.

I have installed some k-tech internals in my 900-ss forks but had a cocked thread in the stock damper rod and I haven't been able to get the k-tech valving to work exactly as i would like, so I thought I would like to try and transplant some gsx-r fork internals to my 900 superlight forks. The k-tech valving seems to have too much high-speed rebound and that would be possible to correct by removing a shim or two from the rebound stack, but because the cocked threads I don't feel like putting any more work to the 900-ss cartridges.

I gathered some information from the net and found the complete internals including fork caps for k4-5 gsx-r 600/750 on ebay quite cheap. They are made by Showa and should be quite high quality compared to the 900ss forks. They have a proper rebound circuit too.

The gsx-r internals are almost the same length as the 900-ss internals. The bottom bolt is exactly the same and so is the fork cap. The gsx-r has blue/gold anodized fork caps and I wanted to keep the stock SS look so I took the caps apart and found that the only difference in the fork cap parts is the rebound adjuster screw/rod and the middle part the damper rod screws in. The damper rod in the gsx-r cartridge is 12mm and 900ss is 10mm, so the middle part has to be taken from the gsx-r. The fork cap body and the preload adjuster nut of the 900-ss forks can be used in with the gsx-r cartridges. You can keep the aluminum-colored cap parts from the 900-ss and swap them to the gsx-r cartridges.

The gsx-r cartridge outer diameter is 24mm and the 900-ss 22.6mm. The 900-ss forks have a 1,3mm thick cup-shaped spacer below the cartridge bottom end that needs to be removed to fit the gsx-r cartridge.

The lengths of the cartridges from bottom to fork cap lip are

900-ss bottomed out 55,9cm, topped out 67,2cm

gsx-r k4 55,3 - 66,9cm

The bottomed out depth of the 900 fork from the bottom of the fork leg to the top of the top tube is 55,2mm. So the stock cartridge will bottom out before the fork leg does. Only if you remove the plastic bottom-out piece (it is removed in the pic below), will the fork leg bottom out before the cartridge. The gsx-r cartridge will bottom out shorter than the 900-ss cartridge (and 1mm before the fork leg) so it should not be an issue.

I assembled the fork legs today with gsx-r cartridges and they seem to fit ok. However, I forgot to take the gsx-r springs and spring spacers with me so I had to leave them out. So no test ride yet.

The whole swap can be done without removing the forks from the bike, only the front wheel needs to come off, so it's quite an easy job.

I'll report the riding impressions as soon as I can get the springs (I forgot them to another town so it will take a few days).

The fork length will be about 4mm shorter after this mod

a pic from the cartridges side by side (the fork caps are already swapped)

I think this could be a cheaper and easier alternative to swapping to sbk forks or re-valving the stock cartridges, if you can just find the gsx-r internals cheap. I think some other year gixxer fork internals would probably work too (k1-3 and srad 750) but I can't confirm it because I don't have the parts. If someone has them, please post the measurements.